-

Colata della lega di alluminio

-

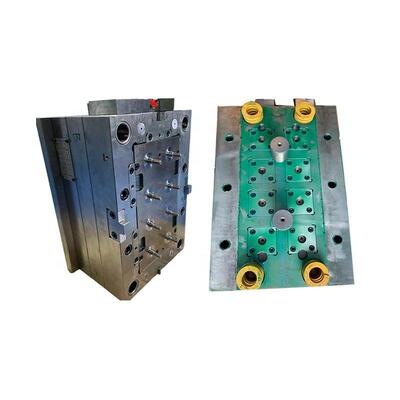

Muffa della pressofusione

-

stampi di metallo fuso

-

Muffa della pressofusione in alluminio

-

Muffa della schiuma di ENV

-

Muffa persa della schiuma

-

Lingottiera della sabbia

-

alluminio colata di stampo permanente

-

Alluminio Die Gravity Casting

-

Muore la lavorazione con utensili della fusion d'alluminio

-

Muffa dei ricambi auto

-

Multi cavità stampo

-

Muffa della testata di cilindro

-

muffa di alta precisione

-

Servizio di stampa rapido 3d

-

Greg HenkRingraziamenti per la vostra ospitalità gentile. La vostra società è molto professionale, noi avrà cooperazione piacevole nell'immediato futuro.

Greg HenkRingraziamenti per la vostra ospitalità gentile. La vostra società è molto professionale, noi avrà cooperazione piacevole nell'immediato futuro. -

Lobo di LionelBuona società con servizio e alta qualità piacevole ed alta reputazione. Uno del nostro fornitore affidabile, merci è consegnato a tempo ed il pacchetto piacevole.

Lobo di LionelBuona società con servizio e alta qualità piacevole ed alta reputazione. Uno del nostro fornitore affidabile, merci è consegnato a tempo ed il pacchetto piacevole.

OEM Multi cavità di plastica per la produzione di muffe da iniezione fabbrica

| Nome del prodotto | Multi muffa della cavità | Personalizzato | SÌ |

|---|---|---|---|

| Demoulding | Automatico | Facendo uso di durezza | >HRC45 |

| Vita della muffa | 50,000-100,000 colpi | Materiale della muffa | EPS |

| Trattamento superficiale | Trattamento termico | Spessore medio della parete | > 3 mm |

| Gamma di prodotti | ricambi auto, luce, industriale, mobilia | Tipo | Colata persa della schiuma |

| Evidenziare | Produttore OEM di stampi per iniezione in plastica,Stampaggio ad iniezione di plastica della multi cavità,fabbrica di stampi per iniezione di plastica su misura |

||

Produttore di stampi a iniezione di plastica a più cavità OEM

a stampo a più cavità è un sistema di stampaggio che produce più prodotti identici simultaneamente all'interno di un singolo stampo.

Metafora principale: Come uno stampo per cuocere una torta. Uno stampo a singola cavità può cuocere una sola torta alla volta. Uno stampo per torte "a più cavità" (come uno stampo a sei tazze) può cuocere sei torte identiche contemporaneamente.

Principio di funzionamento: In processi come lo stampaggio a iniezione, la pressofusione o lo stampaggio, plastica o metallo fuso viene iniettato o riempito in più cavità identiche simultaneamente attraverso un sistema di canali di distribuzione all'interno dello stampo. Dopo un ciclo di stampaggio, è possibile ottenere più parti identiche.

Gamma di prodotti stampi a più cavità

Trasporti, attrezzature per macchine agricole, macchine edili, impianti di conservazione dell'acqua, voli spaziali e aviazione, macchinari chimici, trasporto marittimo e così via.

Caratteristiche degli stampi a più cavità

1. Efficienza di produzione estremamente elevata: questo è l'obiettivo primario. Ad esempio, la produzione completata da uno stampo a 16 cavità in un ciclo di produzione equivale a 16 esecuzioni di uno stampo a singola cavità. Ciò può ridurre significativamente il tempo del ciclo di produzione e i costi di manodopera delle singole parti ed è lo strumento principale per ottenere una produzione su larga scala.

2. Ridurre il costo del singolo pezzo: sebbene il costo di produzione iniziale degli stampi a più cavità sia più elevato (con design più complessi, più materiali e requisiti di precisione di lavorazione estremamente elevati), quando la produzione raggiunge una certa scala, il costo dello stampo, le ore macchina e il consumo di energia allocati a ciascuna parte diminuiranno significativamente, ottenendo così prezzi unitari altamente competitivi.

3. Eccellente consistenza delle parti: tutte le cavità vengono riempite e raffreddate con gli stessi parametri di processo (pressione, temperatura) contemporaneamente, garantendo teoricamente che tutte le parti prodotte nello stesso lotto abbiano una qualità e dimensioni altamente coerenti, il che è fondamentale per le parti di precisione.

4. Risparmiare risorse di attrezzature: utilizzando una macchina per lo stampaggio a iniezione o una macchina per pressofusione con stampi a più cavità, è possibile ottenere la produzione di più macchine che producono contemporaneamente, risparmiando così spazio in fabbrica e investimenti in macchine.

Specifiche di produzione

|

Nome del prodotto

|

Pressofusione in alluminio

|

||

|

Dimensione

|

Personalizzato

|

||

|

Colore

|

Come da vostre esigenze

|

||

|

Materiale

|

Alluminio

|

||

|

Applicazione

|

Componenti auto, apparecchi di illuminazione, coprilampada, alloggiamento per luci a LED, dissipatore di calore o qualsiasi altro tipo di parti pressofuse

|

||

|

Servizio

|

OEM/ODM

|

||

|

Design del prodotto

|

Personalizzato come da disegni o campioni dei clienti

|

||

Processo di fabbricazione

1. Rivedere il design della parte, i disegni e lo standard di qualità dei clienti.

2. Progettazione e produzione di stampi e utensili

3. Test di stampi e utensili e conferma del campione

4. Pressofusione di grezzi

5. Trattamento superficiale: rifilatura, sbavatura, lucidatura, pulizia, passivazione e verniciatura a polvere e altri requisiti del cliente

6. Lavorazione di precisione: torni CNC, fresatura, foratura, rettifica, ecc.

7. Ispezione completa

8. Imballaggio

9. Consegna

Cosa facciamo

1.Realizziamo stampi/stampi per l'esportazione;

2.Offriamo servizi di stampaggio a iniezione;

3.Servizio di assemblaggio e imballaggio

Servizio post-vendita

Ingegneri esperti forniranno soluzioni tecniche complete a qualsiasi problema si verifichi durante il funzionamento dello stampo dei clienti

Profilo aziendale

Luoyang Liushi mould Co., Ltd è stata fondata nel 2001, che è l'unità di definizione degli standard nazionali per lo stampo per la fusione a cera persa. L'azienda si trova nella città dell'Imperatore del Millennio, nella città dei fiori di peonia di Luoyang. Abbiamo un edificio per uffici di 9800 e un'officina di 22000, ben attrezzata con attrezzature di ricerca, sviluppo, progettazione, fonderia, lavorazione, assemblaggio, trattamento superficiale e altre. È un centro di ricerca e sviluppo e un centro tecnologico municipale di Luoyang.

![]()

I tecnici aziendali possono fornire una guida in loco per l'assemblaggio dello stampo, la produzione di prova, la riparazione gratuita e la tecnologia completa per il processo di fusione a cera persa in base alle esigenze del cliente. Con la filosofia aziendale di "progettazione accurata, produzione snella, miglior servizio, qualità perfetta", ci sforziamo di fornire prodotti e servizi soddisfacenti per i clienti. Dopo anni di sviluppo, la nostra azienda è diventata il fornitore di stampi preferito di molti produttori di fusione a cera persa e il fornitore esclusivo.